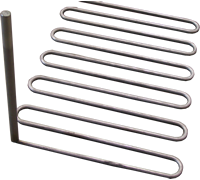

More surface area. Rigid and self supporting

More surface area. Rigid and self supporting

Rod or “Rod Overbend” Elements for applications up to 2100°F (and higher with Moly & Tungsten).

We have the capability to make various geometries specific to your application. Often, the rod elements are kinked to increase the space between the elements and the furnace wall.

We custom design and manufacture mounting provisions (hangers, hooks), and ceramic insulators for securing these elements to the furnace as needed.

Specifications

Typical Applications

- Carburizing, Annealing, Hardening, Sintering, and Powdered Metal Applications

Temperature Capabilities

- Temperatures up to 2100°F and higher with Molybdenum (Mo / Moly) or Tungsten (W)

Typical Materials Used

- Material Types: Ni-Cr (80/20, 70/30, A, AA), Fe-Cr-Al, Moly, Tungsten

- Material Sizes: Up to 1/2″ Dia. Element Material

Recent Projects

- Rod Element Pit Furnace

- 30KW Rod Element Annealing Furnace

- Moly Rod Element Sintering / Powdered Metal Furnace